Cleanrooms stand out as unique projects because each one must adapt to the specific needs of every client. These environments are designed to perform highly delicate and detailed tasks under strict air quality control. Their uniqueness makes their design and execution a highly precise and specialized process.

When developing these spaces, several factors come into play: the intended application, the acceptable particle concentration (ppm), the facility’s location, the type of manufacturing process, as well as cost and delivery times.

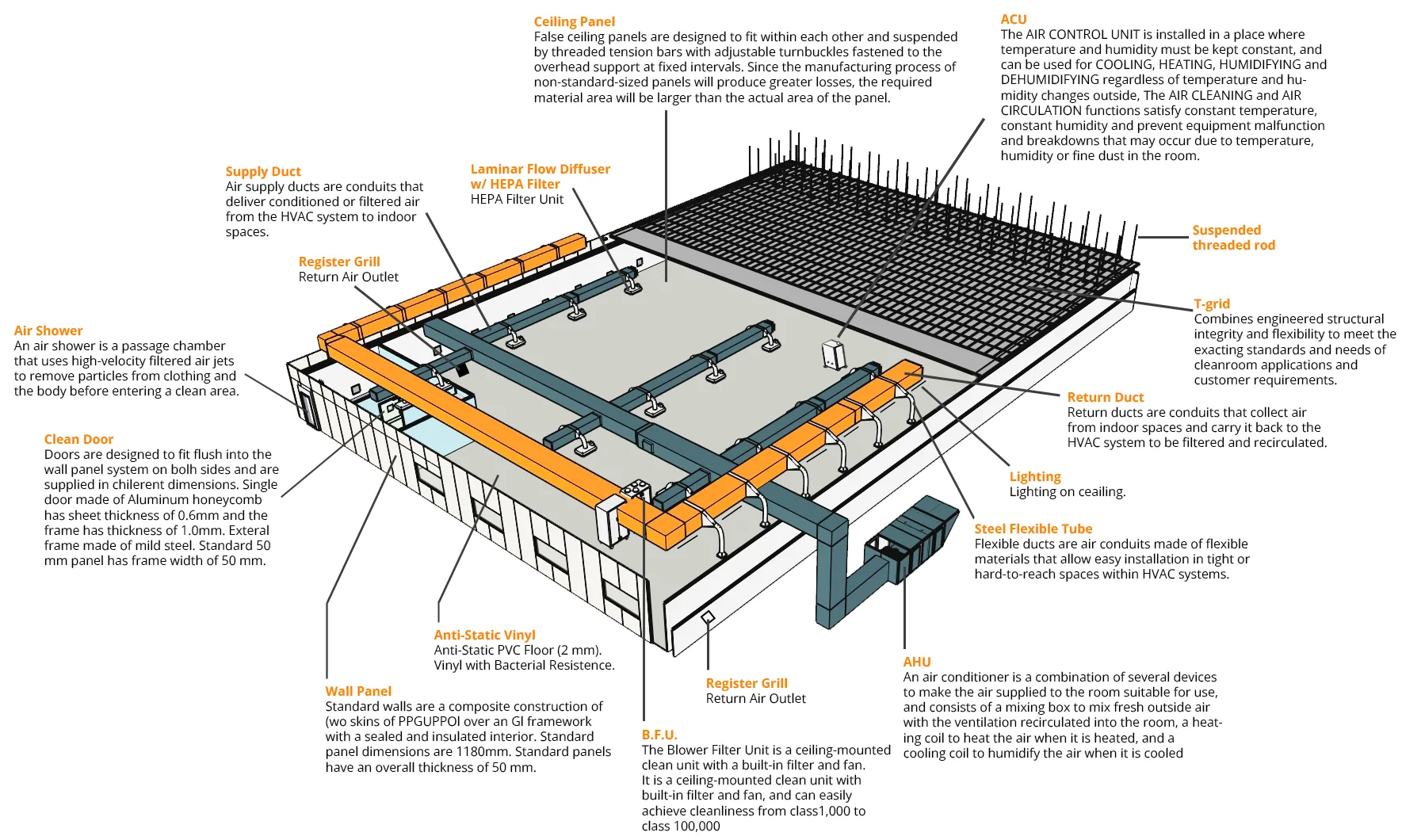

As mentioned, the main challenges lie in the very nature of these rooms and the demanding standards they must meet. Yet, there is one condition that all Cleanrooms must fulfill: air particle control. In essence, a Cleanroom is a space where airborne particles are carefully regulated for a defined purpose. To reduce the introduction, creation, and accumulation of particles inside, it is essential to manage:

m²

Installed

Clients

Served

Projects

Completed

Customer

Satisfaction

| CLASS | >0.1 um | >0.2 um | >0.3 um | >0.5 um | >1 um | >5 um | FED STD 209E equivalent |

|---|---|---|---|---|---|---|---|

| ISO 3 | 1,000 | 237 | 102 | 35 | 8 | Class 1 | |

| ISO 4 | 10,000 | 2,370 | 1,020 | 352 | 83 | Class 10 | |

| ISO 5 | 100,000 | 23,700 | 10,200 | 3,520 | 832 | 29 | Class 100 |

| ISO 6 | 1,000,000. | 237,000 | 102,000 | 35,200 | 8,320 | 293 | Class 1,000 |

| ISO 7 | 352,000 | 83,200 | 2,930 | Class 10,000 |

Partition Panels

HEPA Filter

HEPA Box

Air Shower

FFU (Fan Filter Unit)

Pass Box

Damper

Clean Bench

Clean Booth

Clean Stocker

Aseptic Material Van with UPS

Clean Shoe Sole Washing Device

Clean Hand Washer, Sterilizer & Dryer

Smoke Generator for Airflow Visualization